Recently, Gamm obtained 4/5 in the Sustainability Rating for SMEs according to the standard practice guidelines of UNI 134:2022.

This recognition is the result of a period of renewal within the company that began in 2008 with the target of reducing energy consumption and environmental impact.

It has been a long journey, characterised by continuous investments in systems, machinery and new methods of production but also by our increasing awareness, with the goal of making Gamm a truly sustainable company.

The first major investment took place in 2010 and made it possible for us to use an air treatment unit to make use of the heat emitted by our machinery while melting plastic to power a battery, which in turn brings the temperature of the water used to heat the premises to 30°-35°. By doing this, we have recorded savings of 38% in gas consumption.

Subsequently, we completely overhauled the system that supplies power to our machines, to modernise it and minimise energy losses.

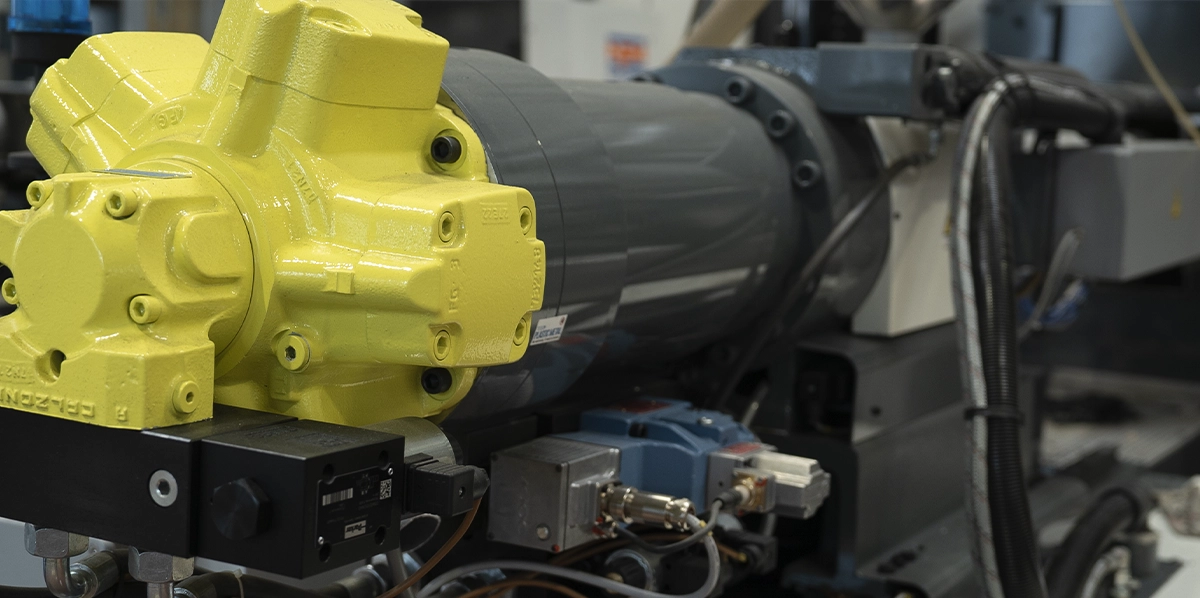

In 2016 we began replacing all our product moulding machinery, shifting from hydraulic presses to hybrid machines, with a drastic reduction in the tonnes of oil used and with considerable savings in electricity.

In addition, in collaboration with Plastic Metal, our partner for the supply of moulding machines, we have created a circular economy of waste material by using “co-injection”: the thermoplastic waste material of each casting is ground on the machine and immediately re-injected into the core of the finished product (thus eliminating the dehumidification step).

This means that 40% of the weight of the article is made up of the waste material we produce, while maintaining the same mechanical, technical and heat resistant characteristics.

These are just a few of the practical measures we have undertaken to ensure that our production of plastic items respects the planet we live on as much as possible.

Do you need more information?

Send us an email, we will be happy to answer all your requests.

Read other articles

Debouncing mallets available again

After extensive research and negotiations, our MEL debouncing mallets will be reintroduced into our product lineup and will be available from September 2024.