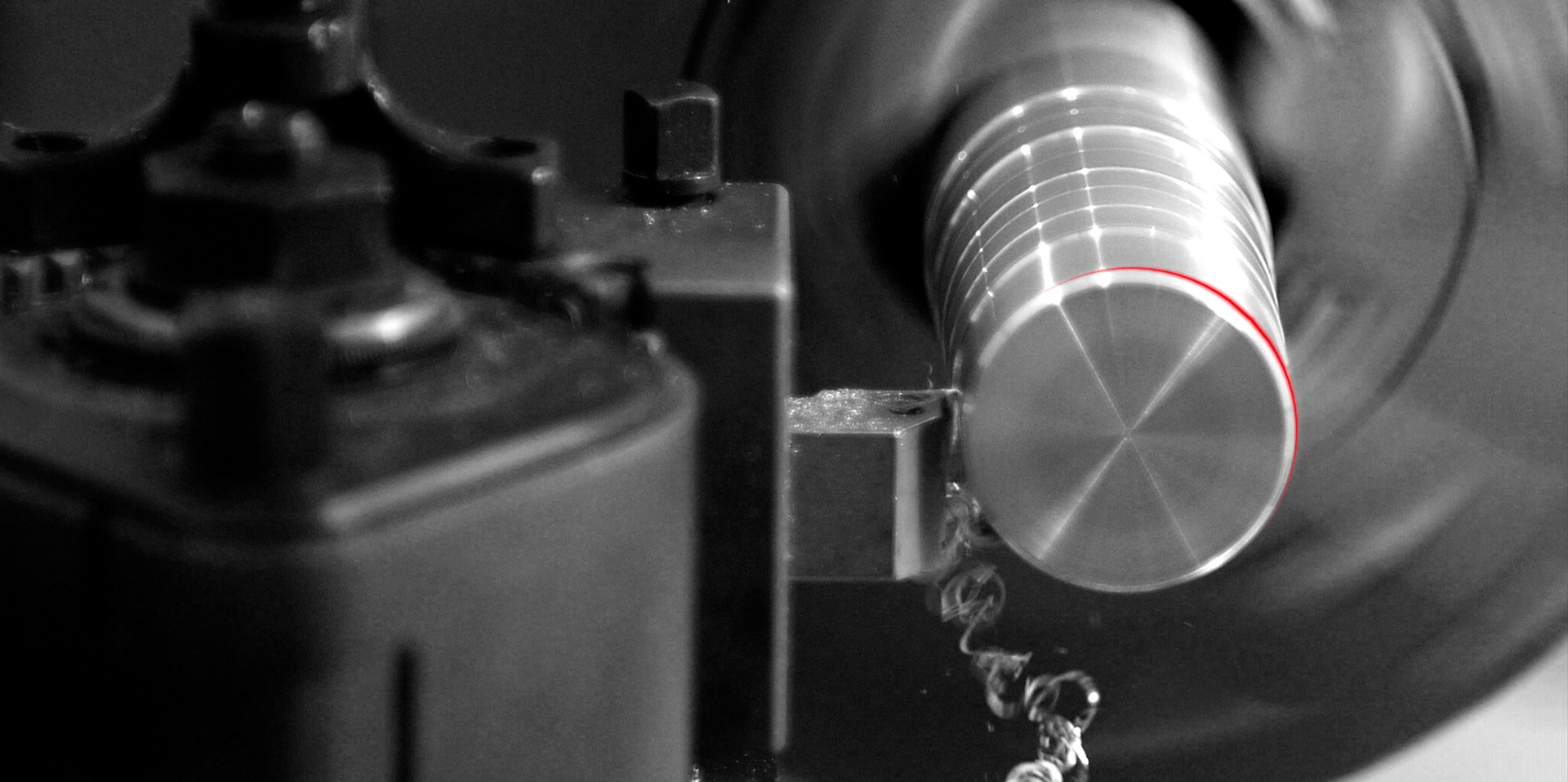

Gamm, a company specializing in the production of thermosetting and thermoplastic components for a wide range of industrial applications, has recently introduced a small turning facility within its headquarters in Montecchio Maggiore (VI).

Thanks to the new in-house turning facility, Gamm now has the capability to directly produce a significant portion of brass, galvanized steel, or stainless-steel inserts needed for the manufacture of many plastic and bakelite items, such as:

This means the company has greater control over the quality and timing of production, eliminating dependence on external suppliers and significantly reducing delivery times.

For example, prior to the introduction of the in-house turning facility, the production of a special item took 4 to 5 weeks just to obtain the required metal insert. With the ability to produce these metal parts in-house, special items can now be completed in just two to three weeks, allowing Gamm to respond more quickly to customer needs and reduce delivery times.

Do you need more information?

Send us an email, we will be happy to answer all your requests.

Read other articles

Debouncing mallets available again

After extensive research and negotiations, our MEL debouncing mallets will be reintroduced into our product lineup and will be available from September 2024.